Lag Screw Swage Stud System - Miami Stainless

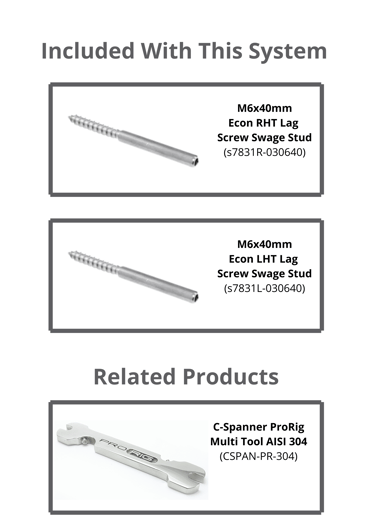

The Lag Screw Swage Stud System is a streamline stainless steel wire balustrade system for straight and angled sections using timber posts. This is a cost effective system for those who are on a strict budget but want a quality balustrade system.

This method requires Hydraulic Swaging at an additional cost. Wire rope is costed per metre. Factory hydraulic swaging applies tonnes of pressure onto the fitting in order to secure the wire into the swage end of the fitting. When you order this system it will come pre-swaged to your specifications.

How to Install A Lag Screw Swage Stud System?

Step 1: Mark out and pre-drill all end posts with 4mm pilot holes at a depth of 45-50mm. Drill 7.5mm holes into all intermediate posts.

Step 2: Pre-thread the holes in the right hand end post with the right hand lag screw and the left hand post with the left lag screw

Step 3: Screw the right-hand threaded lag screw into the pre-threaded hole the minimum amount for it to hold. Pass the opposite end of the wire through all intermediate posts.

Step 4: Screw the left hand threaded lag screw into the left hand end post the minimum amount for it to hold. Screw in both ends evenly by rotating the wire in the same direction. It is recommended to have a person at each end of the wire twisting simultaneously.

Step 5: Finish inserting the lag screws with a ProRig Multi Tool and tighten until desired tension is achieved. For accurate and consistent tension you will require a tension gauge, however you can measure tension by a deflection test.

FAG

Can I install this method myself?

-Yes, even someone with no experience can easily install all our wire balustrade systems.

Do I need any special tools?

-Because the Lag Screw Swage Stud System arrives at your door pre-made from our factory you will only require common handyman tools such as an electric drill with 4mm and 7.5mm drill bits. You can purchase an optional ProRig Multi Tool for easier installation.

What size and type of stainless steel wire do I use?

-This method is almost always used with 3.2mm 1x19 stainless steel wire rope. This wire is the most functional for stainless steel wire balustrade systems due to its bright surface finish, attractive appearance, durability, strength and low stretch.

What spacings do I need between my wires?

-When using a 3.2mm 1x19 stainless steel wire, you will usually need 80mm spacing (usually 11 runs) between your wires when using a standard one (1) meter high handrail. Visit www.MiamiStainless.com.au for more information on building regulations and requirements.

Can I use this balustrade system on a stair or angled section?

-Yes, the Lag Screw Swage Stud System suits stair or angled sections. As long as the system is screwed into your timber posts at the same angle as the stair or ramp section.

When using the system for timber posts, what size pilot hole should I drill?

-You will require a 4mm pilot hole to a depth of at least 45mm.

What size hole should I drill through my intermediate posts?

-A 7.5mm hole through your intermediate posts will allow the Swage Stud pass through.

What is the maximum length run I can do?

-The Lag screw Swage Stud System can easily span up to 8 meters.

Can I take my balustrade wire around corners?

-It is not possible with this system to take balustrade wire around corners.

Click Below To Subscribe To Our Youtube Channel